You’re Chasing Excellence in Logistics. We Know That.

And we also know it’s not easy — constant time pressure, rising costs, and the relentless need to optimize are a daily challenge for anyone responsible for keeping the supply chain moving.

But we also know this: technology can genuinely help. One of the most powerful tools in your arsenal? IoT — the Internet of Things.

How do we know you need it? Because only 6% of companies worldwide have full visibility into their supply chain. That leaves enormous room to build a competitive edge — to move faster, cut costs, and eliminate costly errors.

What We Don’t Know Is Where You Are on This Journey.

But that’s exactly what this article is for. It helps you match IoT solutions to the real needs of your business — no empty buzzwords, just actionable insights you can start implementing tomorrow.

IoT is Your Competitive Advantage — And It’s Closer Than You Think.

Why are logistics companies increasingly embracing IoT?

First, cost. The declining price of sensors, the rollout of 5G, and advances in cloud platforms have made it possible to track fleets, containers, and goods in real time at a scale we’ve never seen before.

Second, it just makes business sense. IoT means faster deliveries, fewer errors, and greater operational efficiency. It enables you to track everything from raw material origin to CO₂ emissions, product condition, and transport conditions — which makes sustainability targets not just achievable, but profitable.

A Real-World Example: IoT in Action at a Major Logistics Operator

The benefits of IoT are best understood through real-life application. One major logistics operator serving a vast e-commerce network implemented an IoT solution across its distribution centers — with impressive results.

Each shelving unit was equipped with weight, position, and humidity sensors, providing real-time updates on inventory levels, package integrity, and correct product placement.

When stock levels reach a predefined minimum, the IoT system automatically initiates a supplier reorder, allocates warehouse space for the incoming goods, and prepares a route for autonomous AGVs (Automated Guided Vehicles).

If anomalies occur — like a sudden weight drop on a pallet or increased humidity indicating a potential spill — the system reacts instantly. It blocks the affected zone and alerts the staff for intervention.

The impact?

- Stockouts were reduced by 80%

- Inventory turnover increased by 23%

- Final order fulfillment time was shortened by up to 2 hours

- Inventory accuracy reached 99.7%, virtually eliminating the need for periodic stock-taking.

This is just one of many examples of how IoT can transform operations from reactive to predictive — and make logistics smarter, faster, and more resilient.

IoT: A System That Scales

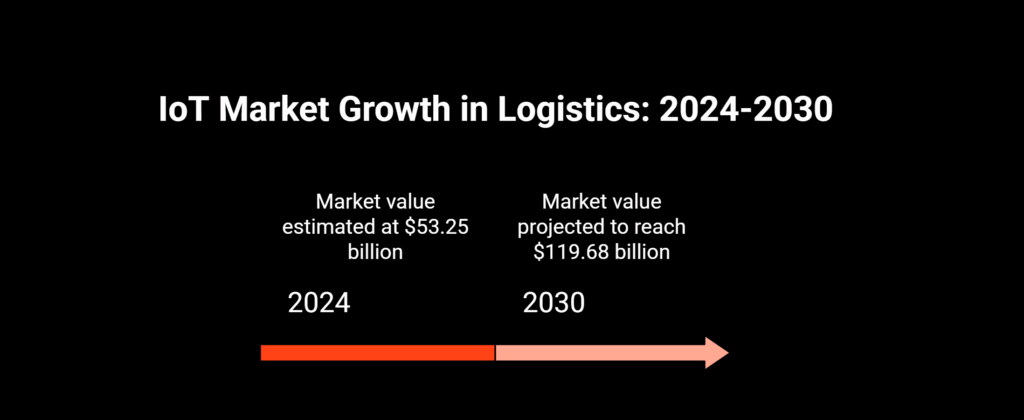

Global data confirms the accelerating adoption of IoT in logistics. According to Research and Markets, the IoT in Logistics market was valued at $53.25 billion in 2024, and is projected to reach $119.68 billion by 2030.

Meanwhile, IDC reports the broader IoT market is set to exceed $1.29 trillion by 2028, driven by innovations in AI, edge computing, and system integration.

For logistics leaders, this means the number of connected devices will surge from hundreds of millions to billions in just a few years.

Smart tracking will become standard, especially for high-value goods — and will be a non-negotiable component of efficient, future-ready supply chains.

IoT empowers companies to blend just-in-time and just-in-case planning, enhance responsiveness, and unlock new levels of operational performance.

It’s not just about keeping up — it’s about getting ahead. Now’s the time to join the front of the pack.

Early Adoption of IoT Is a Strategic Advantage

According to Research and Markets (2024), the Internet of Things (IoT) is set to become a defining force in the logistics sector. That’s why early adoption is critical. Timing is everything — and investments made today are likely to benefit from the network effects and economies of scale that will shape this space in the coming years.

By initiating an IoT project now, companies in the TSL sector are positioning themselves to ride the wave of rapid technological advancement. Soon, advanced IoT-driven systems will become table stakes — without them, competing on cost, service quality, and agility will be almost impossible.

The real question is: what kind of competitive edge is your competition building today that you’ll need to match tomorrow?

When Is IoT the Right Solution?

Managing a supply chain is a complex leadership challenge. One of the biggest pain points? Lack of real-time visibility into cargo and vehicles. While tracking high-value goods is already standard, the true potential of IoT lies in uncovering hidden inefficiencies across the value chain.

Take this example:

A company specializing in industrial waste collection and transport deployed an IoT solution in both its vehicles and waste containers.

- Each container was fitted with fill-level and temperature sensors (to detect potential fire risks), along with accelerometers to alert the system to unauthorized movement or damage.

- Vehicles were upgraded with load sensors and systems that recorded container emptying times.

Previously, the company operated on fixed collection schedules, often emptying half-full bins or arriving too late. After implementing IoT, logistics became dynamic:

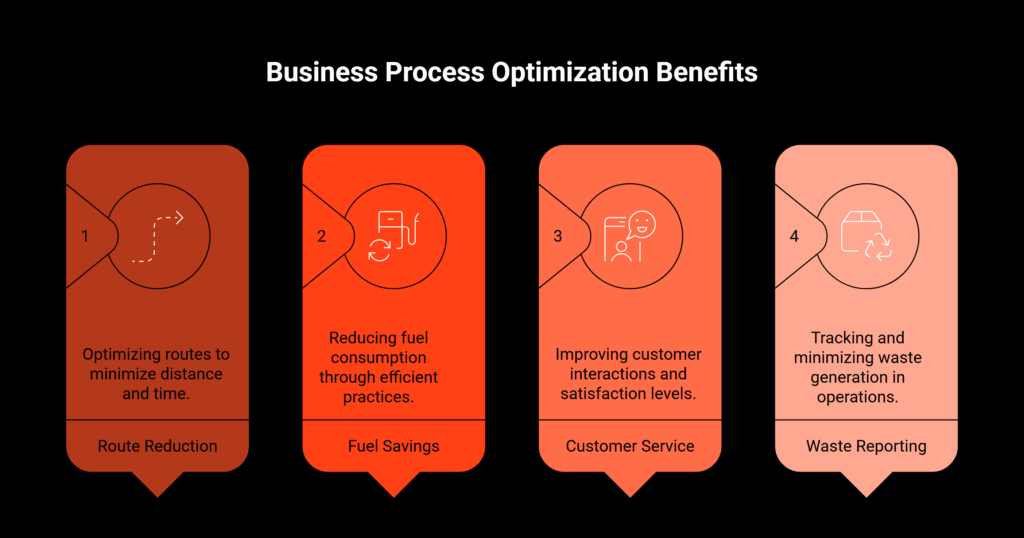

- Routes were optimized daily based on actual fill levels.

- Drivers received real-time alerts for urgent pickups.

The impact was transformative:

- Unnecessary trips were reduced by 32%

- Fuel consumption dropped by 21%

- The company served 18% more customers — without adding new vehicles

- Clients could automatically generate monthly and quarterly waste reports to meet environmental compliance — with no need for manual data collection

IoT Turns Insight Into Impact

This is the power of IoT: it turns traditional, reactive logistics into smart, responsive, and sustainable operations. And in a sector where margins are thin and demands are high, that’s a game-changer.

Would you like this content prepared as a polished article for LinkedIn, a downloadable whitepaper, or a presentation deck for internal stakeholders?

Which of These Challenges Matter Most to You?

Depending on where you are on your digital transformation journey, IoT can be directed toward optimizing your people, shipments, or vehicles.

In every case, real-time data access gives you greater control and opens up new opportunities for optimization. Being able to immediately respond to changing conditions — whether it’s cargo temperature, vehicle delays, or route disruptions — means you can prevent damage and reduce financial losses before they occur

Sensors can provide critical insights into transport conditions, while vehicle telemetry data helps improve route planning and enables automated delay notifications. Mapping bottlenecks across the process allows you to reduce operational errors and improve delivery punctuality.

Combine this with data analytics, and you get a powerful reporting tool — invaluable for stakeholders like your CEO, COO, or CFO, who need both operational and strategic clarity.

IoT in Transport and Logistics: How It Works, What It Changes

By now, you know that IoT isn’t just a trend — it’s a tool for building real, lasting competitive advantage. Of course, the impact depends on your business goals and the challenges specific to your organization.

IoT can monitor fuel levels, vehicle health, or even driver behavior. The key lies in accurately mapping your needs, so you can choose the right IoT strategy for your logistics operations.

So — what’s your primary goal?

- Reducing the number of lost shipments?

- Gaining the ability to dynamically reroute in case of disruption?

- Cutting complaints and damage-related costs?

- Building customer trust through transparency?

- Automatically identifying damaged packages via photo recognition before delivery?

The Internet of Things could be the answer.

But remember — IoT is not just a concept. It’s a suite of concrete technologies that drive real improvements in transportation and logistics.

Let’s take a closer look at how these technologies actually work — and how they can address the unique needs of your company.

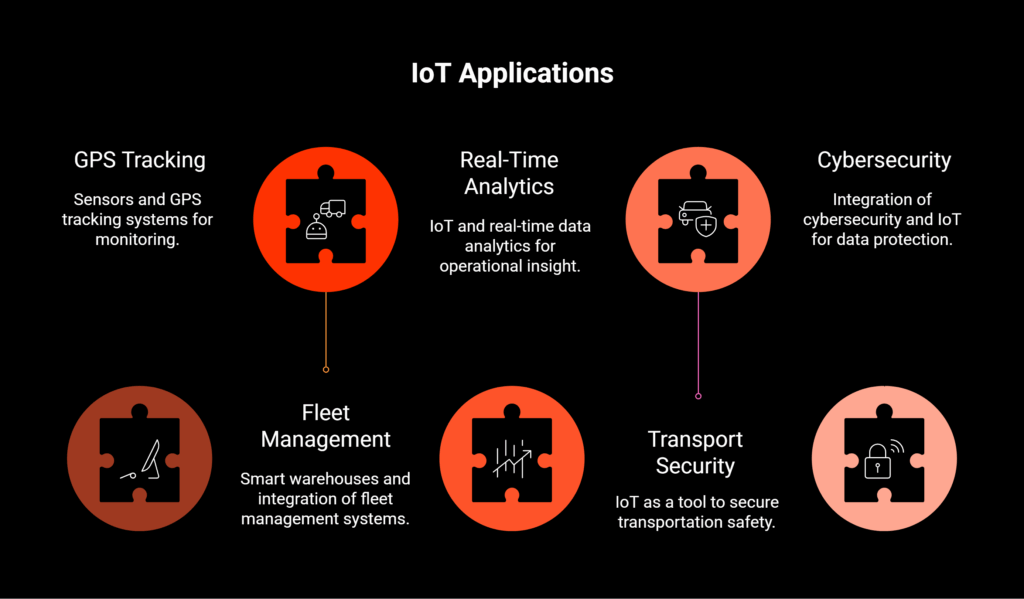

The Power of GPS Trackers and IoT Sensors

Imagine small devices that you can easily place inside a shipment or on any vehicle. These are IoT sensors and GPS tracking systems.

They empower you to:

- Monitor your shipments in real time

- Track exact location, temperature, humidity, or shocks

- Optimize transport routes based on live traffic and weather conditions

This not only improves visibility but helps avoid delays, cuts fuel costs, and enhances customer satisfaction with accurate delivery estimates.

Smart Warehousing and Fleet Management Systems

In traditional warehouses, inventory tracking is manual and error-prone. Smart warehouses use IoT sensors to automatically track inventory levels, item location, and storage conditions. You know what you have, where it is, and if it’s being stored under the right conditions.

Case in point:

A manufacturing company used custom racks to transport goods. Customers were supposed to return these racks, with a deposit in place. But delays and unprofitable return trips were common.

Solution: Small GPS trackers on the racks. Now, the company sees their real-time location, schedules returns during nearby deliveries, and improves customer service.

On the fleet side, IoT + WMS/TMS integration means:

- Full visibility into vehicle movement and load conditions

- Automated process management

- Real-time reporting for CEOs and COOs

Real-Time Analytics: From Data to Decisions

IoT sensors collect a massive amount of operational data. When analyzed in real time, this data becomes a goldmine for smarter business decisions.

For example:

- Monitoring cold-chain transport helps prevent spoilage

- AI-based analytics identifies patterns that humans might miss

- Predictive alerts for maintenance, spoilage, or security threats become actionable

This is especially vital for perishable goods like food, medicine, or horticultural products — where even minor delays or environmental changes can result in major losses.

IoT as a Tool for Transportation Security

IoT enhances security through early detection of risks:

- Unusual routes or stops

- Unauthorized cargo access

- Suspicious driver behavior

These are flagged by AI anomaly detection, allowing companies to respond before losses occur.

Advanced systems also integrate with public safety networks — triggering law enforcement or anti-terror responses when severe threats are detected. Business benefits include:

- Reduced downtime

- Better asset protection

- Stronger reputation through proactive safety

For companies operating in high-risk zones or under strict regulations, this is a game-changing differentiator.

Cybersecurity in the IoT Ecosystem

IoT isn’t just smart — it’s secure.

Using SSL/TLS encryption, IoT networks ensure all data — from logins to commands — is protected at the same level as online banking. With device-level authentication, only verified, trusted components can join your network.

Best practices include:

- End-to-end encryption

- Access authorization

- Regular firmware updates

This ensures resilience against growing cyberthreats in an increasingly connected logistics world.

Use Cases and Industry Success Stories

Route Optimization

UPS uses IoT to plan vehicle routes more efficiently — saving fuel, shortening delivery times, and improving ETA accuracy.

Sony’s Visilion solution enhances visibility and delivery precision while reducing costs. Features like shock detection, geofencing, and route alerts help protect high-value cargo.

Geofencing for Secure Delivery

A logistics firm implemented geofencing for sensitive cargo. Vehicles leaving approved zones triggered alerts, enabling real-time responses to theft attempts — and even preventing a hijack.

Automation benefits included automated arrival notifications, which reduced unloading delays.

Predictive Maintenance with Telematics

Volvo Trucks uses IoT-based diagnostics to predict mechanical issues before breakdowns occur — minimizing downtime and increasing vehicle lifespan.

OBD2 interfaces feed real-time data into fleet management systems, improving driver behavior analysis, fuel optimization, and maintenance schedules.

Fleet & Driver Management: The Ecologic Case

IT-SOLVE partnered with Ecologic to build a powerful IoT-driven SaaS platform. It tracks driver behavior and supports large clients like Unilever, PKO Leasing, and Philip Morris with global fleet management.

Cold Chain Monitoring

Walmart uses IoT to monitor temperature and equipment health across their cold chain — ensuring food safety and minimizing downtime from freezer failures.

Key Takeaways for Logistics Leaders

IoT is not just an innovation. It’s a strategic business enabler.

It delivers:

- Real-time visibility across your supply chain

- Smarter, faster decision-making

- Optimized inventory and routing

- Lower operational costs

- Improved security and compliance

For CTOs, it means measurable value:

- Better data for reporting and decisions

- Greater automation and control

- Higher service quality

This Is Not a Cost. It’s an Investment.

IoT transforms how logistics works.

It turns complex operations into automated, data-driven ecosystems — ready to adapt and scale with your business.

Thank You for Reading

In the next installment of our IoT in Logistics series, we’ll explore implementation best practices and project roadmaps.

👉 Ready to plan your IoT initiative?

Click the banner to schedule a free consultation with our experts.